Antique Automobile Wiring Supplies

If you wish to make your own wiring harness or repair your existing wiring we sell all the materials used in our production. Since these items are normally stocked, once we receive your material order it can be filled within a couple of days.

To make your own wiring harness you need a wiring diagram (schematic). The best schematics are found in the shop manual for your car. The schematic will show you the correct colors, function, and sometimes wire gauge for each wire. Some schematics, though not all, will also show factory optional equipment like heater, defroster, radio etc.

Refer to your original wire harness to double check wire gauges, trace wire layout and measure wire lengths. When you make your new wire harness it will help to run the new wires over the old harness. This way you can make sure that the wires run in the same pattern as original and will fit like the original harness. You might want to add a little more to the length of your new wires to make it easier to install if your placement is a little off.

Suggestions for making your new wires:

- Crimp and solder all your terminals and any splices with rosin core solder. This will insure good connections that will not vibrate loose

- Try to use as few splices as possible. When taping splices seal both ends of the splice and overlap the tape to get several layers over the splice. If you have several splices in the same area then stagger the splices. This will keep the size of your harness down and prevent the splices from rubbing against each other as you drive.

- Our neoprene rubber sleeves are easier to install on the wire before you strip the wire and put on the terminal.

Braiding Service

For original plastic wire harnesses that you want recovered, you should remove the original braiding and make any repairs. We will not braid over any wires where the insulation is damaged and bare wire is showing. We do not carry any wire with plastic insulation so we cannot do any repairs. Also any plastic harness attachments should be taped on either side in the correct position.

So we can braid your wire harness correctly tape the wires every six inches with electrical-tape. Where a wire comes out tape it on either side or for a branch tape the junction like a T. Enclose a sample of the original braiding.

Normally we will braid the wire harness and send a bill when we return the wire harness. Turn around time is normally 1 week or sooner, depending on the braid pattern being run on the equipment.

Call us before shipping the wire harness so we can give you the factory address and so we can be on the lookout for your package. Ship the wire harness to us via United Parcel Service ( we do not trust the U.S. Postal Service with original wires ).

*Fill in the order form information.*

Prices

$ 6.25 machine setup for each braid pattern.

$ 5.00 for each foot of braid material,

$ 1.00 for each braided branch ( to cover added labor ).

$ 25.00 Shipping

All prices subject to change without prior notification.

Note: The following pages of materials and information is offered for the “do it yourself” restorer. When ordering wire you must give us the auto make, wire gauge, color, and length. When ordering neoprene rubber tubing, non metallic loom, or stainless steel conduit you must give us the part number and length. When ordering terminals or connectors you must give us the part number and quantity.

Premium Quality Cloth Braided and Lacquered Wire

All wire has modern automotive PVC insulation, which is covered with cotton braid then lacquered for original appearance. When ordering you must tell us automaker, wire gauge, color, and length.

Wire (for each color) must be ordered in multiples of 5 feet. Example: If you need 4 foot of wire, you must order 5 foot.

Examples of Tracer Patterns for Standard Wire and General Motors Wire

Note: General Motors Color Codes are used in the pictures below.

Color Codes: Red, B – Black, G – Green, W – White, Y – Yellow, BR – Brown, BL – Blue, O – Orange, N – Natural/Tan , OAK – Yellow Base with 2 Red & 2 Black Crossing Tracers

Standard Wire

Standard Wire Price Chart (***Must be ordered in increments of 5ft only.)

Special General Motors Wire

Beginning in 1934, General Motors specified that most wires used were to have a natural cotton color base (a light tan) with single or crossed colored tracers for identification. In many GM wiring diagrams (schematics) the natural base color is not shown, only the tracer colors are designated.

(***Must be ordered in increments of 5ft only.)

NOTES ON ALL GENERAL MOTORS HARNESS SYSTEMS We have done a great deal of research on General Motors wiring harnesses in order to provide you with the most authentic wiring systems possible. While doing this research, we had the opportunity to study original harness blueprints and specifications for some General Motors products. All of the data we examined specified that the wire was to have a natural cotton base color (a light tan) braided over the rubber insulation, with tracer colors woven in for wire identification. The tracer colors would consist of a single thread parallel tracer or two single thread crossing tracers, as specified on the harness blueprints. After the cotton braid was applied to the wire it was to be given a protective coating consisting of a heat, oil and water resistant varnish. This protective coating would color with age and cause the original wire to appear dark yellow, orange, or brown. All the wire we use for General Motors vehicles conforms to the original color codes as specified by the manufacturer. One note on our General Motors harness systems: At this time we cannot supply the original type GM twist connectors, the rear body plug, or the turn signal switch plug. We do provide substitute connectors used in that era and instructions for the salvage and reuse of your original plugs if you so desire. We have been unable to find a supplier whose connectors have the original appearance and quality to meet our standards.

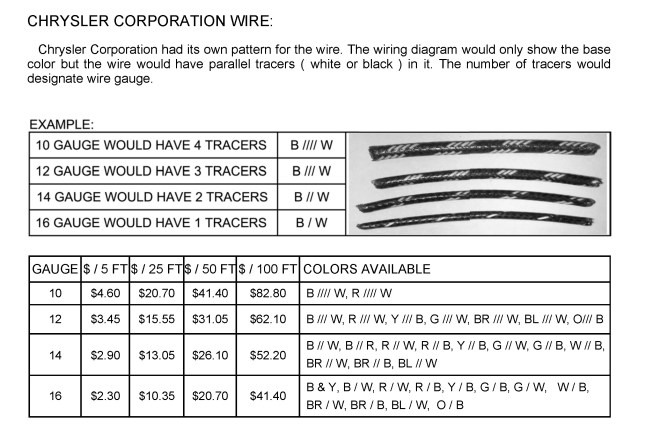

Chrysler Corporation Wire

Chrysler Corporation had its own pattern for the wire. The wiring diagram would only show the base color but the wire would have parallel tracers (white or black) in it. The number of tracers would designate wire gauge.